Let's Talk Bulk Bags

Circular Economy Spotlight on Bulk Bags

Bulk bags are an essential component of mining operations within the Bowen Basin. They are primarily used to transport and store stone dust, which plays a critical role in passive explosion barriers designed to suppress shock and reduce the risk of further ignition during underground explosions. Typically opaque and made from woven fabric polypropylene, these bags are robust, practical, and widely used across the region.

But what is happening to them today?

When managed well, bulk bags can have a long service life and can be reused many times where no signs of degradation are evident. Unfortunately, due to their polymer make-up, end-of-life pathways remain limited. Large numbers of bags still end up in landfill or are stockpiled on-site without a clear reuse or disposal strategy. With thousands used across the Bowen Basin each year, this contributes to a significant volume of avoidable plastic waste.

Yet their durability, consistent structure, and relatively clean post-use condition make them ideal candidates for recovery, repurposing, or recycling under existing in-state programs.

Two Practical Solutions for Bulk Bag Management

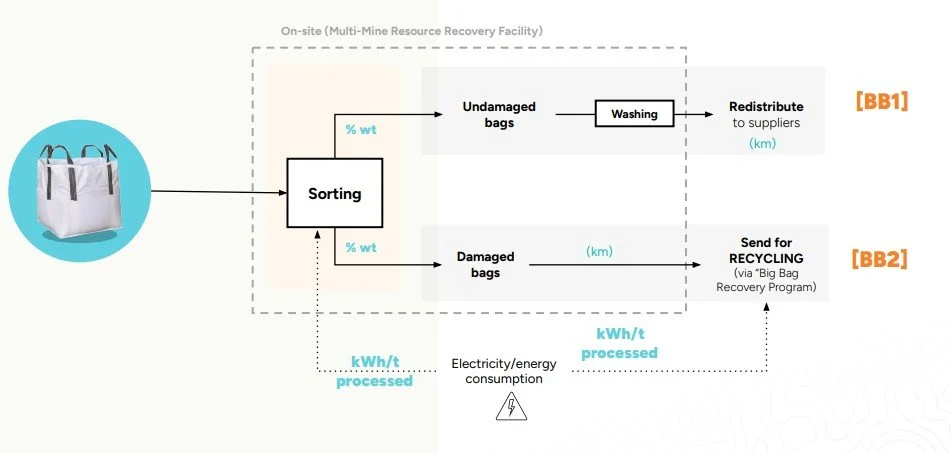

To address this challenge, two solutions were developed to manage woven polypropylene bulk bags, focusing on reuse wherever possible and downstream recycling for damaged or contaminated units.

1. Sorting, Washing, and Redistribution

Reusable bags (those with Safety Factors 6:1 or 8:1) are identified through simple visual inspection, then cleaned and returned to suppliers or operators. This on-site process extends packaging life cycles, reduces procurement costs, and keeps materials circulating within the supply chain.

2. Recycling Damaged Bags via the Big Bag Recovery Program

Bags that are damaged, contaminated, or rated at Safety Factor 5:1 are compacted and sent off-site for recycling through programs such as the Big Bag Recovery initiative in Queensland. Here, polypropylene material is processed into plastic pellets that re-enter manufacturing streams, keeping valuable resources within the circular economy.

The Way Forward: A Hybrid Circular Model

While both pathways deliver similar economic returns, their strengths lie at different stages of the value chain. A hybrid model is recommended:

Reuse bags wherever safe and feasible, particularly where suppliers support take-back programs, and recycle the remainder to ensure full diversion from landfill.

Together, these solutions offer a practical, low-barrier approach that supports emissions reduction, material recovery, strong economic value, and regional job creation. A circular future for bulk bags in the Bowen Basin is both achievable and already within reach.